Etched Molybdenum Foil

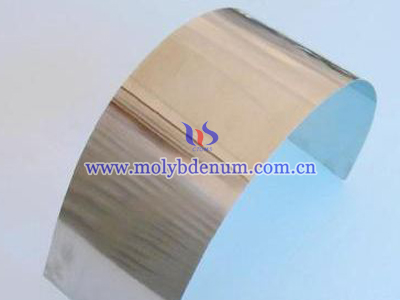

Etched molybdenum foil, of all metals, is used widely because its coefficient of expansion is the closest to quartz. The elliptical shape produces an air and gas tight lead into the lamp envelope, thus preventing filament degradation during lamp operation. Our company provides elliptically shaped etched molybdenum foil for hermetic sealing of quartz lamps.

| Sizes available for ribbon | |

| Thickness | 0.005" to0 .04" |

| Width | 0.30" to 0. 945" |

Etched molybdenum foil leads can be welded assemblies, which is used as the lead wires in many types of hard glass or quartz encapsulated devices for high temperature applications. They are used as internal and external electrical connection and mechanical support, plus a hermetic sealing capability for pinch seals. So they are widely used in mercury arc lamps, tungsten-halogen cycle lamps, infrared heat lamps, and certain electronic and instrumentation applications.

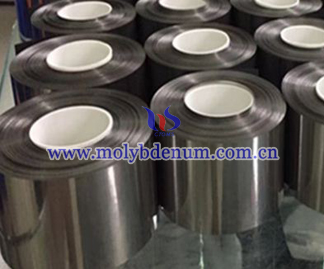

Molybdenum foil is made from molybdenum sheet. Compared with molybdenum sheet, molybdenum foil is thinner and much available in lead making. Meanwhile, it is rolled very thin without creating pin holes or leaker lines. With this advantage, molybdenum foil can be used as etched lead and applied into lamp field.

Molybdenum foil is electronically etched after rolling, and under stringent controls, to combine elliptical shape with the proper thickness and width to special requirements of each customer. Of course, they are cleaned, annealed, inspected and spooled before shipment.

Our company provides qualified etched molybdenum foil.